Category: General

Country: India

Parisa Nagabhushanam

Faculty – Retired

Indian Institute of Handloom Technology,

Ministry of Textiles, Govt. of India, Salem, TN

+91- 94439 96325

Email: parisabhushan@rediffmail.com

“India Shines” the very exiting slogan but is only for urban population. There are many villages in India and the rural folk in these villages are leading their lives under Below Poverty Line (BPL). They find it very difficult to meet the 3 essential requirements of: 1) Food, 2) Shelter, and 3) Clothing.

Though we are in 21st Century, it is often seen in villages that many rural folk wearing patched dress. This patched dress is not designed for them by any textile designer but it is made by them because Necessity is the Mother of Invention. Purpose of this patch arrangement is to make use of the torn out dress for survival. Reason is economical problem. Source for the existence of Today’s Fashionable patchwork dress is the casual wear of rural gypsy folk. Entire Universe is running behind Fashion though there is no exact definition for it. Patched dress of rural India became fashion hub among the urban fashion lovers.

Patchwork or "pieced work" is a form of needlework that involves sewing together pieces of different colored pattern fabrics into a longer patterned cloth. The longer patchwork design cloth is usually based on repeat patterns built up with different colored / design pieces. These shapes are carefully measured and cut into straight or basic geometric shapes making them easy to piece together. Precise joining makes for patchwork that lies flat without puckers.

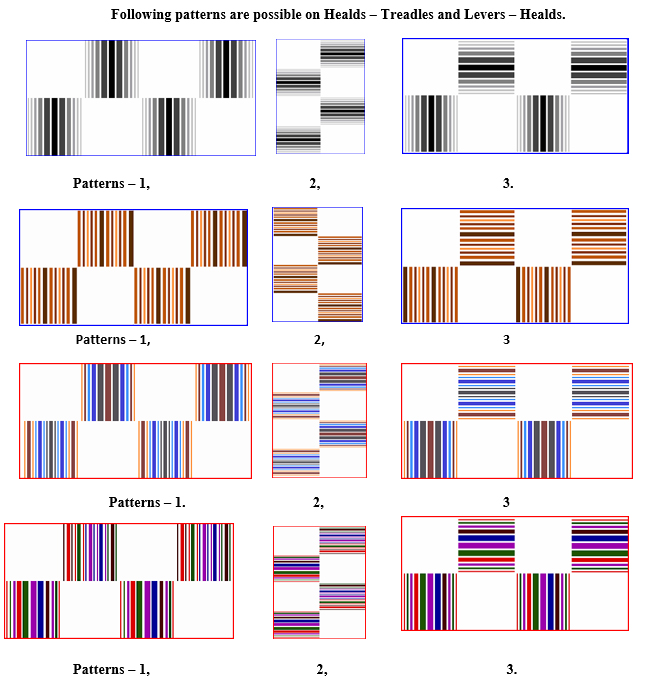

DIFFERENT PATTERNS PATCHED DRESS MATERIAL

Of late patchwork dress became an important fashion tool among the younger generation and demand is increasing day by day. To meet the above demand, supply source is; 1) To weave interchanging double cloth with combination of different weaves in different patterns and size (Reversible woven patch fabric) & 2) To weave different size colour / pattern single cloth and join together. If four different patterns are required for patching, weave four different fabrics (single cloth) on four different looms. Cut the fabrics to required size and stitch together to form a continuous cloth (Non – reversible). This is ready for garmenting.

In case of style (1) above, it is reversible woven patch fabric; possibility for higher production, less manpower, wastage is very minimum and economically viable. Style (2), required patterns are woven on different looms, cut each pattern into required size and stitch together to form a continuous cloth. This is ready for garmenting. In this style after patching the fabric becomes non – reversible. Since this style is two stage processes, weaving on multiple looms, takes long time, unexpected wastage, huge manpower, puckering effects and lead to financial implications. Hence end product becomes very expensive.

Present article of, “Reversible Woven Patch Fabrics” weaving is possible on any existing loom. Fabrics woven are neither double cloth nor single cloth but in combination of two or more weaves. Hence, “Reversible Woven Patch Fabrics” are tightly woven, compact structures and economical. Patterns are vertical stripes, horizontal stripes, checks and dice checks (diagonal arrangement). It is possible to plan any number of different sized patterns and / or number of colour combinations in the full width. Weaving machine may be Handloom or Powerloom or auto loom. In case of Handloom there will be no fatigue on weaver because weaving is in fly shuttle. Production is comparatively higher and better end product than the existing patched fabrics. Reversible woven patch fabrics are best suitable for dress material, home furnishing, and quilt from the loom and also cost effective.

The following are few patterns for reference.

Above reversible woven patch patterns are ready for end use like garmenting, home furnishing and quilt. When used to make a quilt, this larger patch woven fabric becomes the "top" of a three layered quilt, the middle layer being the batting, and the bottom layer the backing. To keep the batting from shifting a patch woven quilt is often quilted by hand or machine using a running stitch which can outline the individual shapes that make up the patch woven fabric top or the quilting stitches can be random or highly ordered overall patterns that contrast with the patchwork composition.

All the above patterns results compact structural fabrics, ready for garmenting and cost effective comparatively to the piece patched fabrics. Some of the above motives are technically reversible and others commercially.

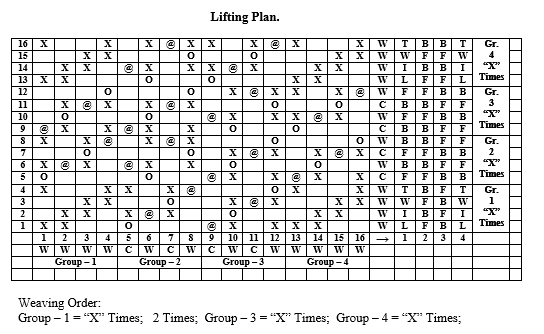

Loom Requirement:

A) Multi treadle frame loom (Handloom) – No additional attachments like Dobby and/or Jacquard,

B) Frame loom with vertical dobby (Handloom),

C) Pick – At – Will Powerloom with dobby,

D) Rapier loom with dobby,

E) Air jet loom with dobby.

Advantages:

A) Possibility is on any existing loom.

B) Woven patch fabric is from a single loom and reversible.

C) Possibility for higher production.

D) Less manpower and fatigue on weaver.

E) Fabric wastage is zero.

F) Cost effective and economically viable.

G) Number of patterns in different size is possible.

Copyrights © 2026 GLOBAL TEXTILE SOURCE. All rights reserved.