Category: DYES AND CHEMICALS

Country: United States

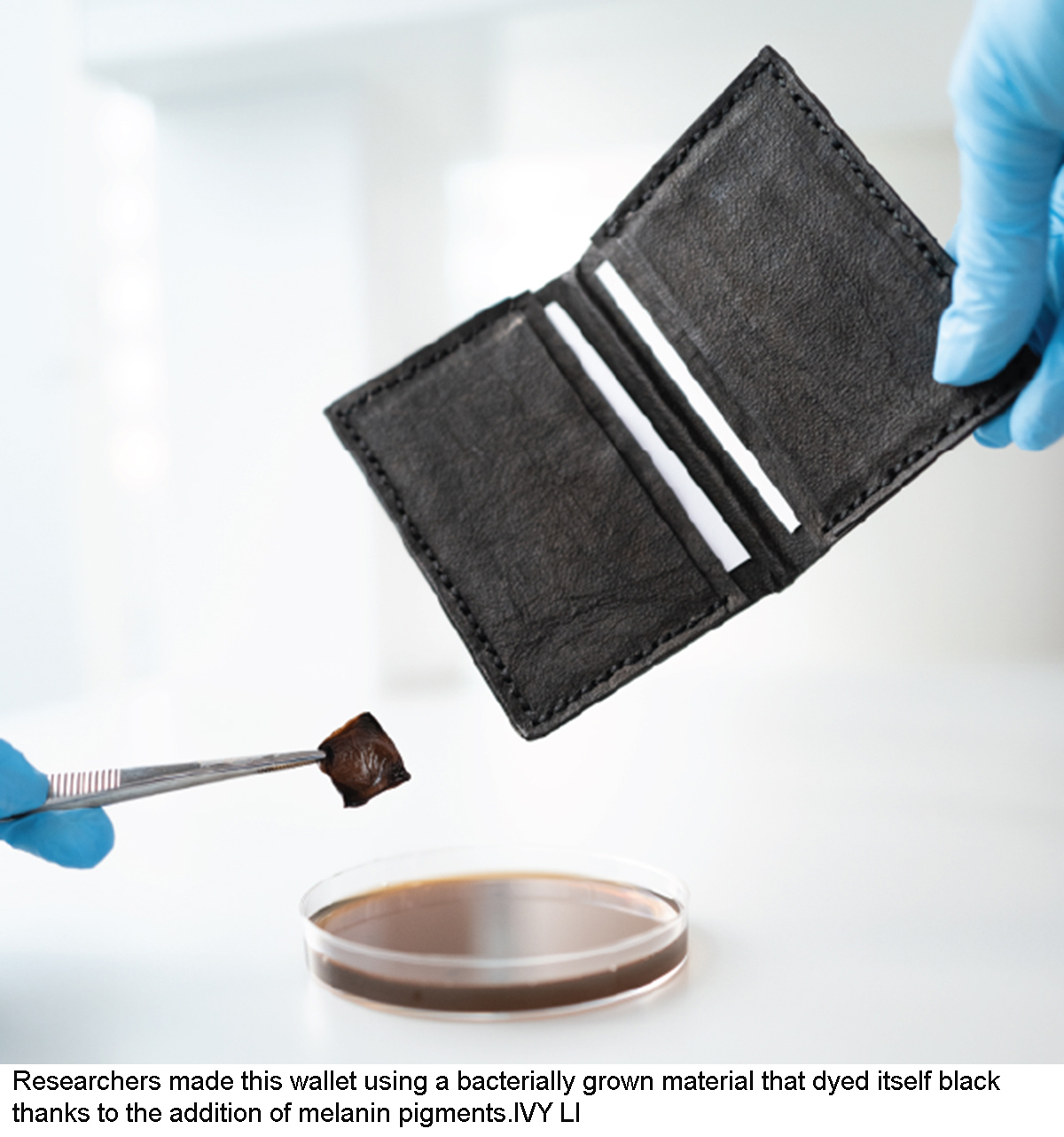

Researchers created a wallet and part of shoe by genetically engineering kombucha bacteria to produce melanin

By Madeline Reinsel

9th April 2024 5:45 PM ET

For sustainability-minded fashionistas, materials made by fast-growing, eco-friendly bacteria offer an appealing alternative to leather or faux plastic replacements such as “pleather.” Yet coloring or adding patterns to these bacterial textiles can still mean working with environmentally harmful dyes. A study published last week in Nature Biotechnology may offer a solution: genetically engineering bacteria to produce melanin pigment so the material can dye itself.

“This is an example of how biology can provide products that not only have remarkable properties, but can also be manufactured with a very low footprint and be sustainable,” says Sara Molinari, a synthetic biologist at the University of Maryland who was not involved in the study. Bacteria-generated textiles are “a compleunittely new approach in material manufacturing.”

The leather substitute is made of cellulose, an essential structural material in plants that is also produced by several species of bacteria. In recent years, researchers and designers have started to produce textiles from bacterial cellulose as an alternative to leather and pleather, some of which are already on the market.

The durable textile, which scientists can quickly grow into custom shapes, has many of the same properties as traditional leather. But although bacterial cellulose textiles have fewer environmental impacts than leather or plastic, they are naturally beige. That means they are typically colored using traditional dyeing processes, which can use large amounts of water and release harsh chemicals into the environment.

Researchers from Imperial College London (ICL) wondered whether bacteria could be coaxed into producing cellulose that was naturally dark-colored. To find out, they genetically engineered a cellulose-producing bacterium, Komagataeibacter rhaeticus—the same bacterium that helps ferment kombucha—by adding a gene from another bacterium that produces black melanin pigment. Melanin is what gives color to tissue throughout the natural world, including human skin, eyes, and hair.

Early experiments weren’t promising. The cellulose material appeared pale and faded, rather than dark black as the researchers had hoped. Then they discovered that the medium used to culture K. rhaeticus in containers in the lab was becoming more acidic as the bacteria grew, stymying melanin production. To solve this problem, the researchers developed a two-step process: After producing the cellulose, they submerged the material in a vibrating bath with the same pH as water, and a rich black color quickly developed. Once they had the color they wanted, the scientists grew sheets of bacterial cellulose to the correct sizes and shapes needed to make a wallet and the upper part of a shoe. Afterward, the scientists use a heat press to kill off remaining bacteria.

“The color was really striking,” says study co-author Tom Ellis, a synthetic biologist at ICL. “Much more so than we imagined.”

The researchers also created designs on the textiles by genetically engineering the kombucha bacteria to produce melanin pigment only when exposed to blue light, which was projected in patterns onto the sheet of cellulose.

The melanin-dyed textiles appear to be just as durable as their undyed cellulose counterparts, researchers noted. “It’s quite hard to achieve something that’s going to be brilliant in the real world, never breaking apart in 10 years, and that also you could then throw in the compost and it would disappear within half a year,” Ellis says. But he hopes that this material might hit those targets.

The team collaborated with a textile biotechnology company, Modern Synthesis, which plans to use the group’s research to create new products. The company did not, however, provide any funding for the research. If the technique catches on, it could provide a template for creating more sustainable materials for the fashion world, Ellis said. He hopes to streamline the pigmenting process so the material can be manufactured more quickly, as well as produce cellulose textiles in a wider variety of colors.

“There’s a big thirst for this in the fashion companies, to have microbially made textiles, and to use biotech to get towards that,” Ellis says.

Molinari says directly modifying the bacteria to produce patterns and colors “simplifies the manufacture by a lot,” which could help manufacturers scale up the technique. But she notes that manufacturers have had trouble ramping up production for other kinds of biotextiles while still maintaining accessible prices for consumers.

For now, sustainability enthusiasts will have to wait for the other bacterially produced shoe to drop.

Courtesy: Science.org

Copyrights © 2025 GLOBAL TEXTILE SOURCE. All rights reserved.