Category: TECHNOLOGY AND INNOVATION

Country: United Kingdom

Aim is to reduce the amount of polymer lost through inefficient flow paths.

By Innovation in Textiles

31st January 2024

Leeds, United Kingdom

The UK’s Fibre Extrusion Technology (FET) has been awarded £50,000 in grant funding to collaborate with the University of Manchester on complex new spin pack and spinneret designs.

The grant is being awarded by a consortium led by AMPI (The Advanced Machinery and Productivity Institute) and NPL (The National Physical Laboratory). AMPI’s Innovation for Machinery (I4M) programme supports businesses in West Yorkshire and Greater Manchester as part of an overall initiative to drive innovation for the UK’s advanced machinery manufacturers to meet the challenges of developing new technology and entering emerging markets.

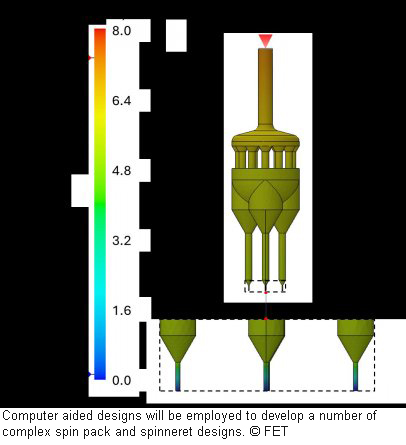

In this project, FET will be working with the University of Manchester to conduct computational fluid dynamics (CFD) studies on a number of complex spin pack and spinneret designs.

The aim is to identify areas of improvement for FET’s spin packs and spinnerets and to use computer aided designs to develop significantly more efficient versions. Improving the throughput of FET extrusion systems will reduce the amount of polymer lost through inefficient flow paths. In turn, the development will reduce the environmental impact of synthetic polymer processing.

FET designs, develops and manufactures extrusion equipment for a range of high value textile material applications worldwide. Established in 1998, its major strength has always been in collaborating with customers in testing, evaluating and developing high value materials with diverse, functional properties.

The funding will provide FET with access to the expertise of four universities and the National Physical Laboratory to develop the next generation components.

Courtesy: Innovationintextiles.com

Copyrights © 2025 GLOBAL TEXTILE SOURCE. All rights reserved.