Category: SERVICES

Country: Germany

By Jamie Stokes

28th February 2025

Testing laboratory Hohenstein and DuPont have collaborated to develop three innovative and reliable test methods for soft ballistic inserts.

Maximising the comfort and mobility of body armour, such as bulletproof vests, is key to the performance and endurance for law enforcement and military personnel. The new methods address the disconnect in existing tests with real body movements and positions.

An interdisciplinary and intercompany team of DuPont and Hohenstein experts developed the test methods, which guarantee a reliable assessment of the specific ergonomic comfort characteristics. “It is in the DNA of Hohenstein to get as close as possible to the user’s reality,” said Dr. Jan Beringer, Senior Scientific Expert at Hohenstein. “With dedicated wear trials, possible discomfort and movement restrictions were determined. Then, leveraging on decades of expertise, tests and equipment to simulate the wearer’s experience were designed, in close collaboration between DuPont and Hohenstein.”

“To meet the critical needs of law enforcement and military personnel, maximising comfort and flexibility in soft ballistic solutions is essential. Developing test methods to evaluate pain and mobility constraints is an important first step. By leveraging Hohenstein’s recognised expertise in textile and wearability, we can advance these solutions to the industry and enhance wearer comfort, allowing personnel to perform their duties with greater efficiency,” said Christophe Djololian, Global Market Development Leader at DuPont.

Three Comfort and Mobility Tests

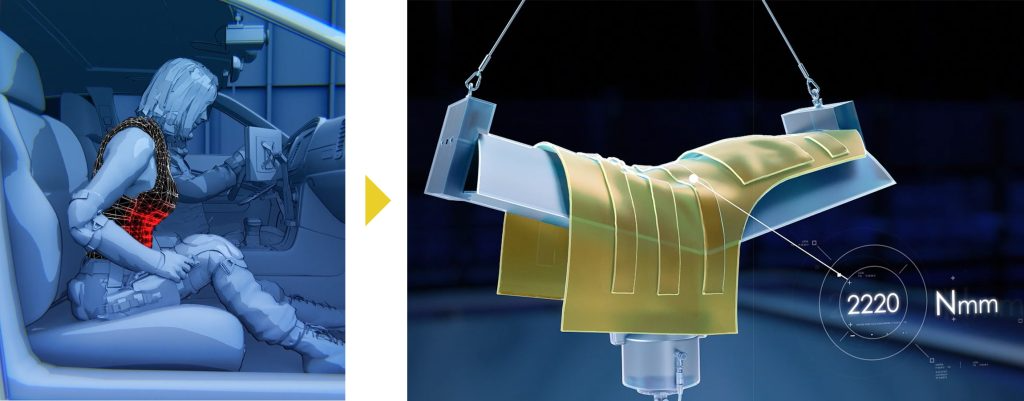

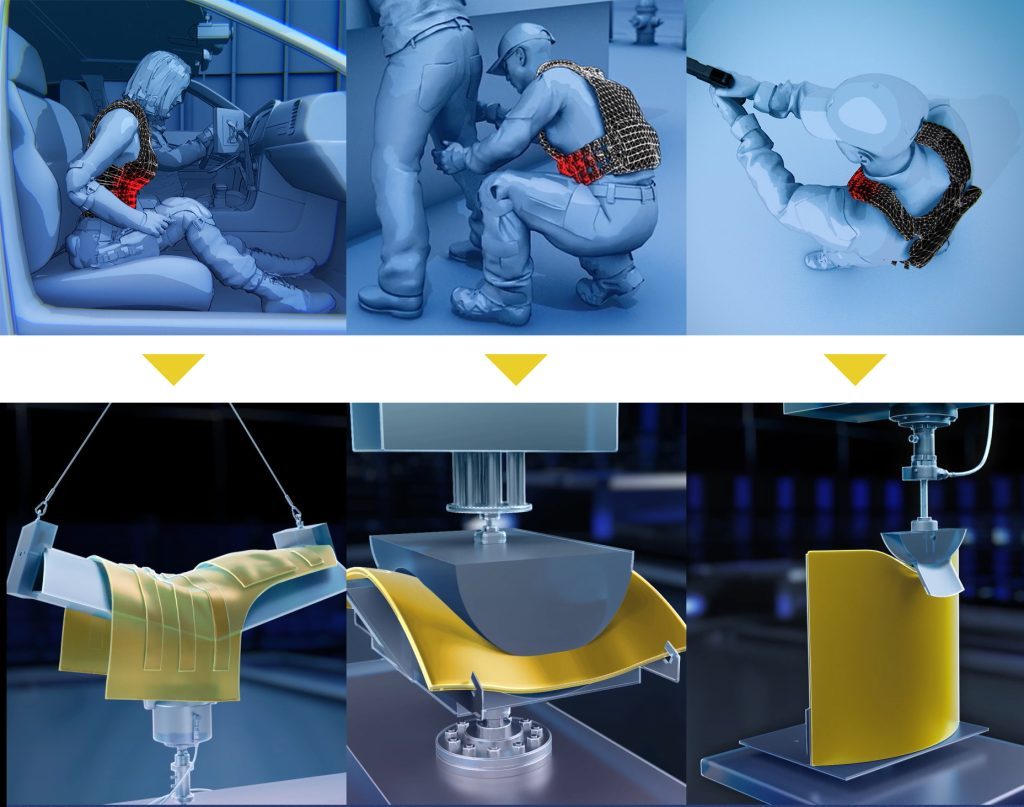

The Lower Costal Bending (LCB) test replicates the bending movement of an upper body. On duty, movements involving multiple bends lead to energy loss and accelerated exhaustion for the wearer. The LCB test quantifies lost energy due to the stiffness of a ballistic garment.

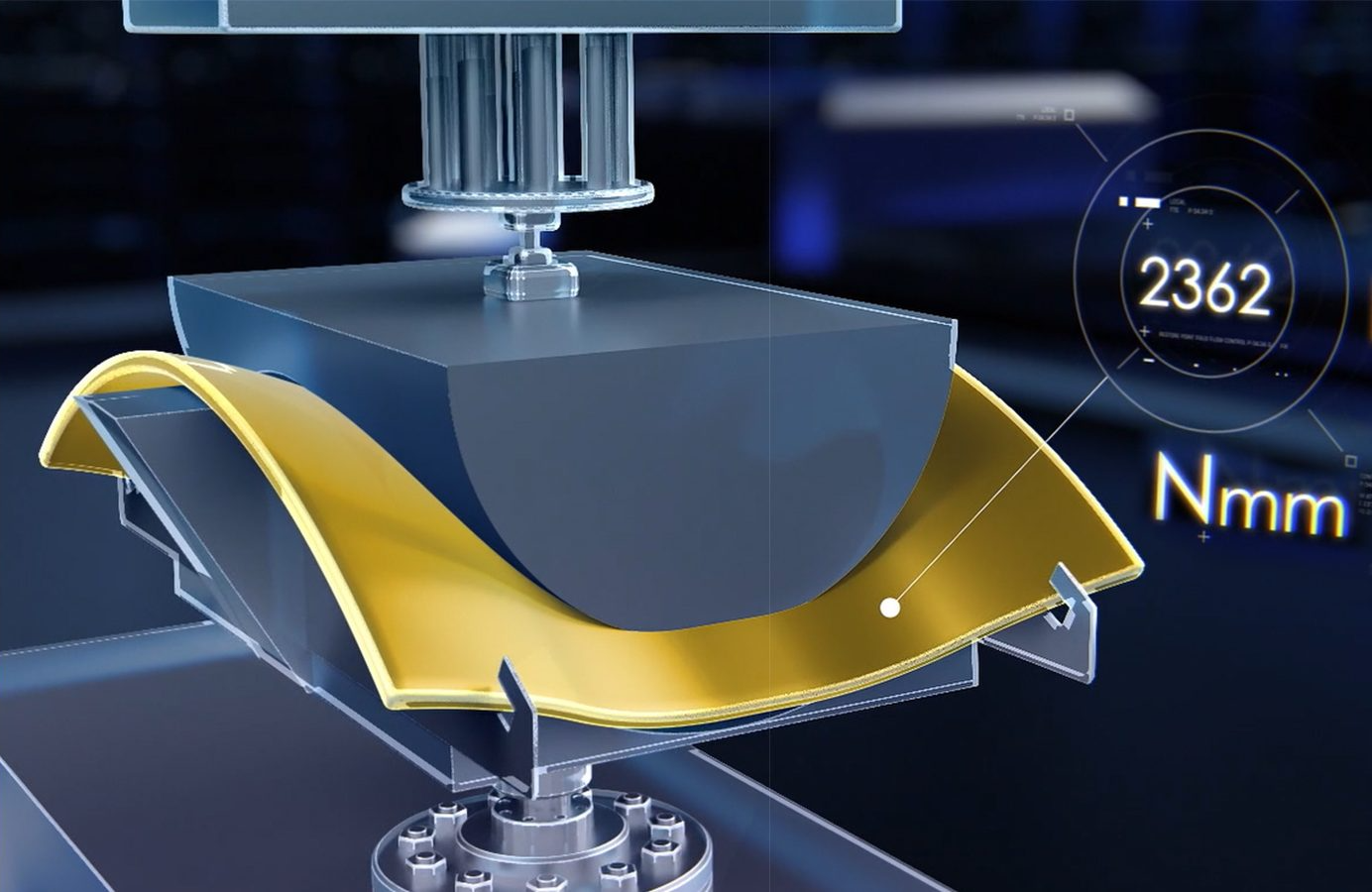

To maximise mobility, ballistic solutions must adapt to the wearer’s body. The Double Curvature Compression (DCC) test replicates the shape of a curved torso and uses digital imaging to assess the gear’s adaptability and mobility in applicable user situations.

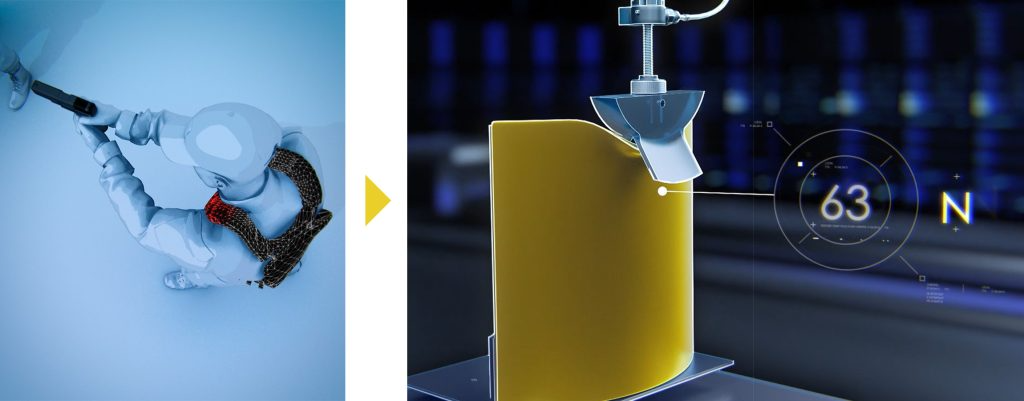

Where the edges of a ballistic vest meet the body – on the lower abdomen, neck or arm – the pressure can cause discomfort. The Edge Pressure (EP) test replicates the shape of the arm and the curvature of a ballistic vest. The EP test quantifies discomfort generated at localised pressure points.

The three test methods to characterise Comfort & Mobility constraint for soft ballistic applications are available from Hohenstein. “Depending on the requirements, we offer different solutions,” explains Dr. Jan Beringer. “Certified third-party and independent testing can be carried out by the experts in Hohenstein’s PPE labs, on specially designed equipment. The test devices are also available for purchase to facilitate product development by body armour manufacturers and solution assessment by end-users.”

Service inquiries, contact:

+49-7143271898

customerservice@hohenstein.com

Further details & free download of test procedure specifications click here.

Courtesy: pciaw.org

Copyrights © 2026 GLOBAL TEXTILE SOURCE. All rights reserved.