Category: FABRICS

Country: India

Region: Asia

Discover the pioneering projects of Nahar Industrial Enterprises over the years!

By GTS_NewsDesk

1st July 2024

The textile industry in India can be traced back to 5000 years ago. It has developed and outgrown struggles of its own through storms and waves. With the growth came large scale textile mills and weaving units dedicated to serving the industry. One such textile group of companies is Nahar Industrial Enterprises Limited. Established in 1949 in Lalru as a woollen worsted spinner and hosiery manufacturer, the group has grown into one of the leading textile giants of Northern India, with a top-of-the-line facility for spinning, weaving, processing, knitting and garment capacities, along with a retail business. In addition to these major activities, Nahar Group is diversifying into new areas like sugar manufacturing, BOPP films, and power generation (solar power, windmills and non- conventional co-generation power plants).

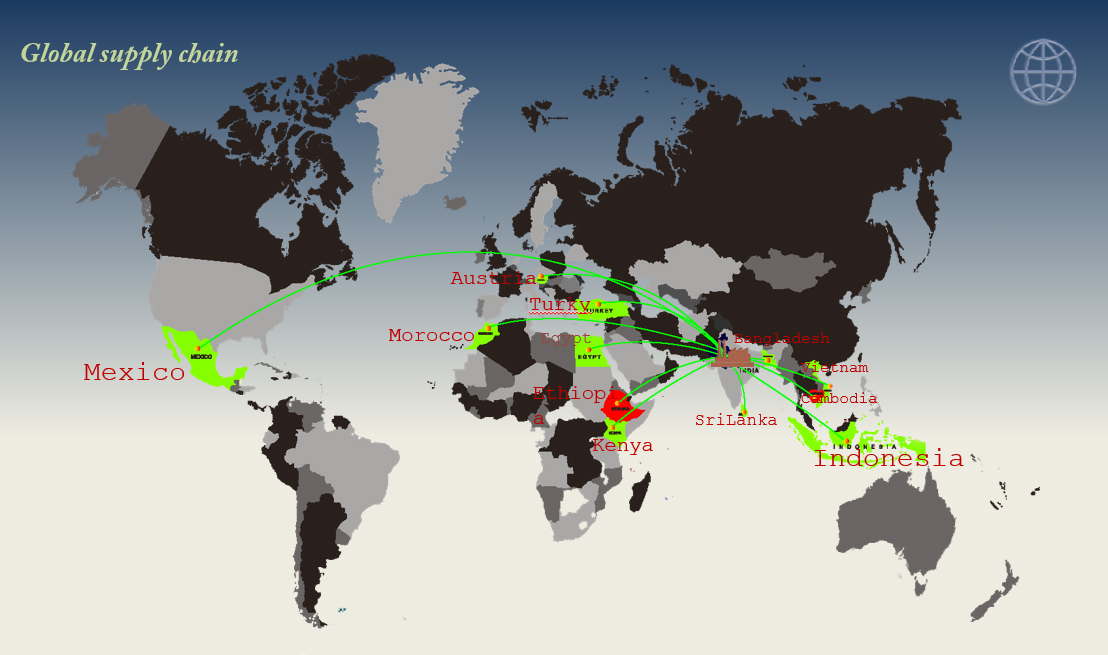

Nahar Industrial Enterprises Limited has various companies under their name, such as Oswal Woollen Mills Ltd., Nahar Spinning Mills Ltd., and Monte Carlo Fashion Ltd. Each is dedicated to different sects within the textile industry. Nahar Industrial Enterprises Ltd. exports their products to various parts of the world, such as Bangladesh, Sri Lanka, Cambodia, Vietnam, Indonesia, Kenya, Ethiopia, Egypt, Turkey, Austria, Morocco and Mexico.

Their factories are top of the line and have the best infrastructure. Their spinning unit has a capacity of 2,54,304 spindles and 7,832 rotors that produce 65,000 tonnes of yarn per annum. Their yarn dyeing capacity is that of 3,805 tonnes per annum, among which, 50-60% is exported and the remaining is sold in the domestic markets. The balance is used for captive production (woven fabrics). They spin yarns in counts of 6’s single to 80’s single and 2/10’s to 2/100’s greige and mercerised yarn in variations of cotton, poly-cotton, cotton- spandex, tencel and other blends. The yarns are made using numerous technologies, such as open end, ring spun, combed, compact, slub, multicount, TFO, Eli-twist and Airjet spinning. Their speciality is however in Giza and Pima yarns.

Moving to their weaving infrastructure, they are equipped with 485 top speed looms with a capacity of 52 million metres per annum. They have top of the line looms such as sample WPG Machine (Suzuki/Karl Mayer), Karl Mayer/Benninger for warping and sizing, Staubli for drawing, air jet (Toyota /Picanol) and rapier (Picanol/Vamatex).

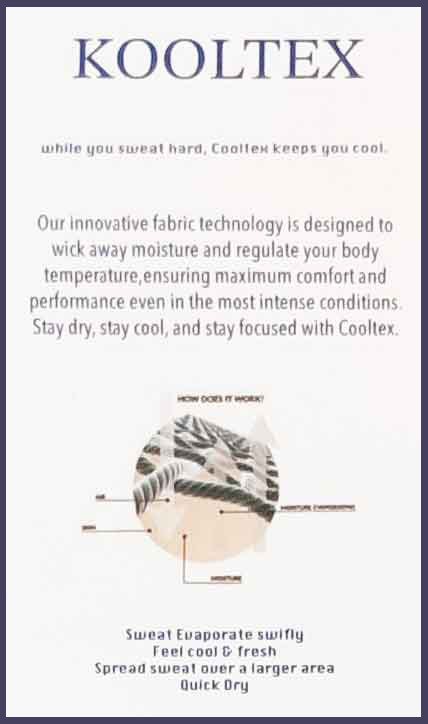

Nahar Industrial Enterprises Ltd. has a processing capacity of 50 million metres per annum for dyed, yarn dyed, prints and RFD/white. Their unit is technologically well equipped with a singeing machine (OSTHOFF) desize, bleaching & mercerize (BENNINGER), pad dry thermosol and stenters, (BRUCKNER & MONFORTS GERMANY for dyeing padders (KUSTERS), rotary printing (Zimmer), Weft straightener (MAHLO) and Peaching (LAFE). They offer various finishes, such as fire retardant, anti-microbial, coolgen finish, Woven Patch Dobby fabric, Kooltex Printed fabric, Reviva Viscose Stripe Shirting fabric, Dispro Print, Excel Ombrey Dyed Shirting, and much more.

They manufacture fabrics in varieties of cotton, cotton poly blends, linen, viscose, tencel, hemp and so much more. The fabrics are widely used for apparel manufacturing, smart textiles (fire retardant, water repellent, etc.), and combat fabrics for the Indian Army and Indo Tibetan Border Police Force. Apart from textile services, they are actively engaged in sustainable policies for raw materials wherein 50% of the total production is sustainable products such as 100% BCI cotton, organic cotton and recycled polyester. They are in the process of scaling this up and making their production systems more efficient and sustainably viable.

Additionally, they cater to the community as they believe to stand responsible for the individuals, the communities and the environment around them. It has been their responsibility to make sustainable contributions to society through sustained actions that will benefit the needy and deserving consistently by catering to sectors of education, environment, sports and health. They are actively engaged in distributing school uniforms to the underserved students, organising health checks, COVID vaccine drives for all their employees and their families, contributing to infrastructure management of government schools, planting 8000 trees in 3 years, etc. to name a few initiatives.

Additionally, they cater to the community as they believe to stand responsible for the individuals, the communities and the environment around them. It has been their responsibility to make sustainable contributions to society through sustained actions that will benefit the needy and deserving consistently by catering to sectors of education, environment, sports and health. They are actively engaged in distributing school uniforms to the underserved students, organising health checks, COVID vaccine drives for all their employees and their families, contributing to infrastructure management of government schools, planting 8000 trees in 3 years, etc. to name a few initiatives.

In their active contribution towards saving energy, Nahar has taken numerous steps. Some of which are replacing lights with LED lights, piped PNG in the entire unit, 100% recycled water, reduction in water consumption at every stage of production, installation of energy efficient compressors, solar power systems, etc. to name just a few. They are also complying to complete product traceability systems by sharing detailed information on fabric production levels and their origin.

From farm to fabric, they share details on the following parameters:

1. Farm detail

2. Ginner detail / TC number

3. Cotton fibre inbound date/month and quantity

4. Yarn lot number and quantity

5. Weaving lot number/ sort number

6. Dye lot number/ PO number

7. Fabric dispatch invoice/ TC number

In conclusion, Nahar Industrial Enterprises Ltd., has exemplified the resilience and evolution of the textile industry in India. Nahar's commitment to service, sustainability, and innovation is unwavering. Their expansive infrastructure, diverse product range, and sustainable practices not only cater to a global market but also reflect their dedication to social responsibility and environmental stewardship. As they continue to lead with cutting-edge technologies and ethical practices, Nahar Industrial Enterprises Limited remains a beacon of excellence in the textile world.

Discover their product range at stall no. D 9/12 at the upcoming Textile Fairs India trade show happening in Pragati Maidan, New Delhi on 18, 19, 20 July 2024.

To know more about Nahar Industrial Enterprises Limited:

Click here

https://globaltextilesource.com/company/nahar-industrial-enterprises-ltd

Copyrights © 2026 GLOBAL TEXTILE SOURCE. All rights reserved.