Category: FABRICS

Country: China

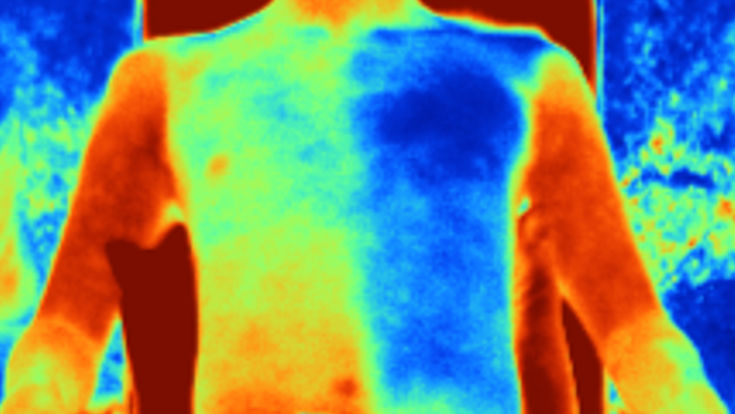

A new material (right) significantly reduces body heat compared to regular cotton (left), as seen in this infrared image. S. ZHENG, ET. AL., SCIENCE (2021) 10.1126

By Alex Viveros Jul. 8, 2021 , 2:10 PM

While it’s easy to engineer clothing that keeps you warm, it’s far harder to come up with an outfit that can keep you cool on a scorching summer day. Now, researchers have designed a fabric that looks like an everyday T-shirt, but can cool the body by nearly 5°C. They say the technology, if mass produced, could help people around the world protect themselves against rising temperatures caused by climate change.

To make clothing that beats back the Sun, fashion designers typically use light-colored fabric, which reflects visible light. But another method reflects the Sun’s electromagnetic radiation, including ultraviolet (UV) and near-infrared (NIR) radiation. NIR warms objects that absorb it and slowly cools them as they emit it. That cooling process, however, is stymied by our atmosphere: After being emitted from an object, NIR is often absorbed by nearby water molecules, heating up the surrounding air.

To speed up the cooling process, researchers are turning to mid-infrared radiation (MIR), a type of IR with longer wavelengths. Instead of being absorbed by molecules in the surrounding air, MIR energy goes directly into space, cooling both the objects and their surroundings. This technique is known as radiative cooling, and engineers have used it over the past decade to design roofs, plastic films, wood, and ultra-white paints.

Human skin, unlike many of the clothes we wear, naturally emits MIR. In 2017, Stanford University researchers designed a fabric that lets MIR from the human body pass directly through it, cooling the wearer by about 3° C. But to work, the fabric had to be very thin—only 45 micrometers, or about one-third the thickness of a lightweight linen dress shirt. That led some researchers to question its durability.

To design a thicker fabric, engineers Ma Yaoguang of Zhejiang University and Tao Guangming of Huazhong University of Science and Technology took a different approach. Rather than letting MIR from the skin pass straight through their fabric, they and colleagues designed a textile that used chemical bonds to absorb body heat and re-emit its energy into space as MIR. The 550 micrometer fabric—made of a polylactic acid and synthetic fiber blend with titanium dioxide nanoparticles scattered throughout—also reflects UV, visible, and NIR light, further cooling the wearer. Even though it looks like a regular shirt, “optically, it’s a mirror,” Tao says.

To test their creation, the researchers assembled a snug-fitting vest, with one half made of their fabric and the other made of white cotton of about the same thickness. A graduate student donned the vest and sat in a lawn chair in direct sunlight for 1 hour. When the researchers measured his skin temperature, the side under the new fabric was almost 5° C cooler than the side under the cotton, they report today in Science. To an infrared camera, the contrast was clearly visible, and Tao says the student could feel the temperature difference.

“This is all interesting,” says Yi Cui, the Stanford materials scientist who led the previous work and whose lab has continued working on mid-IR transparent fabrics. But he adds that, because MIR-emitting technology has so far been used on stationary surfaces that constantly face the sky, the authors of the new work should also measure how well their fabric cools when people are standing or walking. He also wonders whether the fabric works as well when it is loosely fitted, since the cooling element relies on its close contact with the skin.

Evelyn Wang, a mechanical engineer at the Massachusetts Institute of Technology, shares some of Cui’s concerns. But she adds that the work speaks to speedy progress in the area of radiative cooling. “This kind of approach has advantages because it can enable a use of a broader range of materials and feel much more like cotton, which is important for the user.”

Ma and Tao are now reaching out to textile manufacturers and clothing companies to try to get their fabric on shelves. They say the nanomaterial-infused fabric should add only about 10% to typical clothing manufacturing costs. “We can make it with mass production, which means everybody can get a T-shirt … and the cost is basically the same as their old stuff,” Ma says. “It can benefit everybody.”

Alex Viveros is a Diverse Voices in Science Journalism intern for the News section of Science.

Alex Viveros is a Diverse Voices in Science Journalism intern for the News section of Science.

Courtesy: https://www.sciencemag.org/news/2021/07/new-mirror-fabric-can-cool-wearers-nearly-5-c

Copyrights © 2025 GLOBAL TEXTILE SOURCE. All rights reserved.