Category: SUSTAINABILITY

Country: India

Region: Asia

Read on to learn about Sulochana’s contribution to circular textiles in polyester!

31st May 2024

By GTS NewsDesk

India's textile industry stretches back to 4000 BC, with the oldest dyed cotton fabric dating back as far as 2500 BC. It has experienced significant developments since then and has reached incredible heights. The industry has come a long way since the time of the Cholas, Mughals, and British. However, with great heights comes great responsibility. With overwhelming growth and innovations, the industry has also had its downfalls when the surrounding areas began deteriorating, causing immaculate amounts of pollution to rivers, land and air!

“The global textile and garment industry is responsible for 6-8% of all carbon emissions, equivalent to 1.7 billion tonnes of CO2 emissions annually. The industry’s dyeing and treatment processes are also a significant contributor to industrial water pollution worldwide. Moreover, the heavy use of synthetic chemicals in the production of textiles from raw materials poses a further environmental risk”, as mentioned in an article dated April 13th, 2023 and written by Mr. Pratik Gadia as published in TOI. However, the past few years has opened the eyes of many brands and given birth to many sustainable initiatives to aid for a greener future with ethical processes in place for every stage of production.

One such company is Sulochana Cotton Spinning Mills Pvt. Ltd., established in Tirupur. They are a yarn spinning unit with multiple companies under their name. They deal in yarn spinning, fabric weaving, dyeing, mattress manufacturing, etc., and they also have a recycling plant. It is a completely sustainable value chain production management organisation and they do not sell just products, they also provide value added environment benefits to their customers. They operate on 100% renewable energy (95% wind energy and 5% solar energy) and are focused on working sustainably with scientific methodologies and carbon footprint reductions.

Some of their projects are mentioned below:

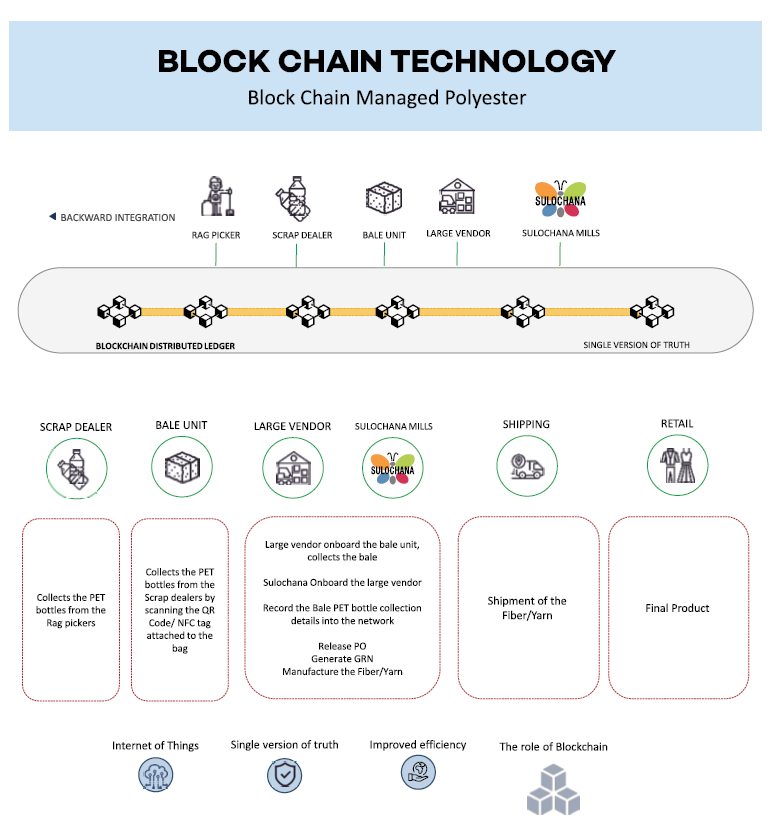

Vertical Textiles - Sulochana is engaged in circular production of textiles by manufacturing 1,35,000 kg of polyester fibre from 80 lakh PET bottles that are collected from landfills and processed in house. Once the PET bottles are processed into PET flakes, they are sent to extract the polyester fibre.

Dope Dyeing - Once the fibres are extracted, they are dyed using a water-less technology called dope dyeing, which does not require any post dyeing wash, hence reducing the consumption of water.

Yarn spinning - They spin the polyester fibres into yarns with various eco-friendly combinations such as micro modal, tencel, viscose, bamboo, etc. - all of which are Canopy approved supply chains.

Certifications - They have all the necessary certifications to manufacture and supply their respective products. Some of them are OEKO-TEX Standard 100, Global Recycle Standard [GRS], Global Organic Textile Standard [GOTS] and World Wide Responsible Accredited Production [WRAP].

With such ethical and environmentally friendly processes in place, Sulochana has been serving the textile industry for the past 31 years.

The textile industry needs many more such initiatives to reduce the impact it has been having for centuries.

This article is an extract derived from the interview with Mr. K.S.I Rajesh, DGM Exports, Sulochana Cotton Spinning Mills Pvt. Ltd. and his team who spoke with GTS Newsdesk at the Bangalore edition of Textile Fairs India, organised on 20, 21, 22 March 2024.

To know more about Sulochana Cotton Spinning Mills Pvt. Ltd.:

Click here

https://globaltextilesource.com/company/sulochana-cotton-spinning-mills-pvt-ltd

Copyrights © 2026 GLOBAL TEXTILE SOURCE. All rights reserved.