Category: MACHINERY

Country: India

Modha Sivakumar’s machine can easily be fitted to a traditional Jacquard-based loom to replace the manual tasks of traditional workers who would have to otherwise lift 45 kg of warp threads with their lower limbs for around 6,000 times a day.

Written by Rahul V Pisharody

Hyderabad | December 5, 2022 12:30:19 pm

In a traditional handloom, a craftsman has to lift 45 kilograms of warp threads approximately 4,000 to 6,000 times a day with both legs while weaving intricate patterns with their hands. But, things are changing for the good. An innovation by a grassroots-level entrepreneur in Telangana has brought relief to a niche group of skilled craftsmen who are forced to quit their vocation due to either disabilities or old age.

Forty-two-year-old Modha Sivakumar has developed a machine that can easily be fitted to a traditional Jacquard-based loom to replace the manual tasks of a traditional worker who would have to otherwise lift 45 kg of warp threads with his/her lower limbs thousands of times a day.

Sivakumar’s ‘Modha pedal-operated machine for handlooms’ was presented the state government’s best innovation award at the Telangana Assistive Technology exhibition organised on the International Day of Disabled Persons Saturday by the Telangana State Innovation Cell in collaboration with the Department of Welfare & Senior Citizens, Department of Women & Child Development at T-Hub in Hyderabad.

The pedal-operated machine for handlooms can easily be fitted to a traditional Jacquard-based loom to replace the manual tasks of a traditional worker who would have to otherwise lift 45 kg of warp threads with his/her lower limbs thousands of times a day. (Express Photo)

The pedal-operated machine for handlooms can easily be fitted to a traditional Jacquard-based loom to replace the manual tasks of a traditional worker who would have to otherwise lift 45 kg of warp threads with his/her lower limbs thousands of times a day. (Express Photo)

“Often, the workers develop knee pain and back pain by the time they are 40-45 years of age and quit weaving. They have no other means of livelihood at that age. Moreover, more than 70 per cent of the weavers in the country are women. In my machine, one can perform the same tasks using pedals or hand switches relieving the legs of the pressure,” Sivakumar told indianexpress.com.

Using pedal switches, a weaver could use his toe for shifting pedals and the hanging warp threads are lifted by the motor fitted to the machine. A BSc Computer Science graduate, Sivakumar is a self-taught innovator in the handloom sector. The pedal operating machine was conceived after he saw a YouTube video of Gottimukkala Ramesh, a weaver from Bhoodan Pochampally in Telangana’s Yadadri Bhuvanagiri district, in January.

Bhoodan Pochampally – a traditional cluster of handloom weavers – received the award for ‘Best Tourism Village’ last December at the 24th session of the United Nations World Tourism Organisation’s General Assembly held in Madrid, Spain. Often referred to as the Silk City of India for its unique Ikat silk saree, over 80 per cent of the households here, roughly about 3,000 families, eke out a living by tie-dying yarn and hand-weaving this premium silk saree.

Ramesh, one of the weavers, lost his legs after he fell under a train in 2016. He could not weave anymore and his family suffered even as an NGO donated his artificial limbs. “I started getting pains and stopped again. Ever since my brother Sivakumar gave me this machine, I have started to weave again without any hassles,” Ramesh told indianexpress.com. He along with his wife now earns about Rs 25,000 to Rs 30,000 a month from weaving about 10 hours a day at their home.

“I spent 17 years of my life developing my first invention, a similar but a more complicated machine for handloom weavers. While it is not in the market yet, the video of Ramesh shook me and it took me about 15 days to develop my second innovation. I developed it just for Ramesh and gifted it to him. While the first machine reduces the investment of weavers, the second machine is a solution to reduce the physical stress on them,” adds Sivakumar.

Sivakumar’s innovation was awarded by the state government as it ensures sustained income for weavers and increased production. (Express Photo)

Sivakumar’s innovation was awarded by the state government as it ensures sustained income for weavers and increased production. (Express Photo)

Quoting central government statistics, Sivakumar says that of a total of 28 lakh weavers across India, over 19 lakh are women and about 10 lakh weavers (both male and female) are above the age of 45 years. He says his machine is not just for nearly 1.5 lakh weavers who are physically distraught but also for all those weavers who wish to reduce the burden on their legs while at work.

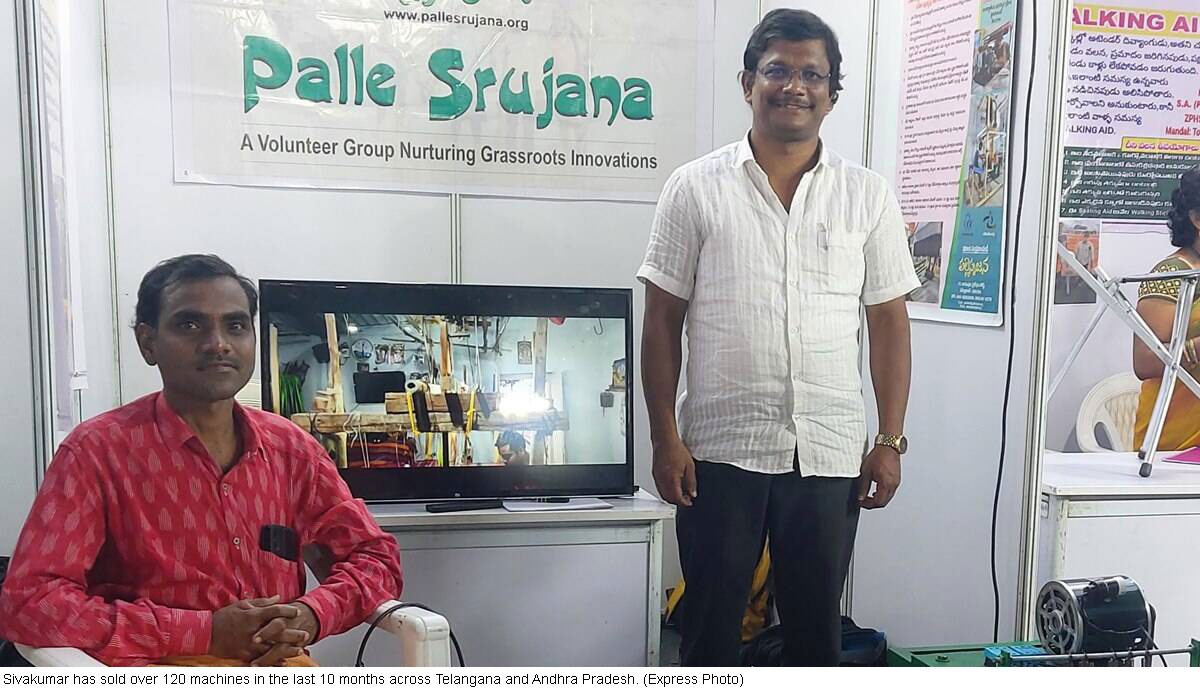

Sivakumar has sold over 120 machines in the last 10 months across Telangana and Andhra Pradesh. “Now that their legs are not exhausted, they can spend more time on the loom and that means, they can produce more and earn more.” The machine costs between Rs 15,000 to Rs 27,000. The cost depends on the number of levers used and based on the mode of operation (toe-operated pedals or hand-operated switches).

Sivakumar’s innovation was awarded by the state government as it ensures sustained income for weavers and increased production. “The quality of sarees in these cases is higher as machines do the lifting consistently and efficiently. The overall production of the industry could go up as well as disabled weavers resume weaving. This will also ensure higher revenues for the families dependent on the specialised craft,” he adds.

Sivakumar says his wife is the backbone of his success, and credits Brigadier P Ganesham of NGO Palle Srujana for mentoring him.

Courtesy: https://indianexpress.com/article/cities/hyderabad/telangana-entrepreneurs-handloom-weavers-physical-distress-state-award-8306378/

Copyrights © 2025 GLOBAL TEXTILE SOURCE. All rights reserved.